PLC and SCADA Systems

As time is passing we are becoming more dependent on software. Software is playing a vital role in the growing development of the world. Friends, today we will talk about those systems which are most needed in industries to run smooth, easily control of any production line or machines and home appliances based on program feeding. Please understand, if we could control the home appliances like AC, Fan, lights etc. through computer, then it would be best.

So, let's know about PLC and SCADA Systems.

PLC :

It means Programmable Logic Controller. The widespread application of microcomputers and programmable logic controllers (PLCs) has replaced the factory floor. It is a digital controller that enables to control the machine by input and output devices. When we want to control or operate a machine in a desired manner, then we will need a PLC (Programmable Logic Controller). Multiple input and output devices can be combined with a PLC. After installing PLC in machine, we can operate in better way, also take desired outcomes from machine. In that reason, it is very beneficial.

PLC helps to convert operation process happening in real time. In this we do not have to change any hardware. That is, it increases adaptability and changeability as compared with hardware. If the machine is in running condition in this production line it collects and gives the data to us.

HOW DOES PLC (PROGRAMMABLE LOGIC CONTROLLER) WORKS?

There are 4 basic operational steps for every PLC :-

1. INPUT SCAN :

It scans all the inputs connected to the PLC and takes data from them and gives it for output.

2. PROGRAM SCAN :

Its work is to implement the program that is input inside the PLC. That is, taking the input under it and converting it to the output. That's the Program scan.

3. OUTPUT SCAN :

It gives instructions to the output devices as to which device to run based on the given data. That's the output scan, either energy and de-energizes all connected devices.

4. HOUSEKEEPING :

This unit is committed to communicate with its internal elements. Only then processing is possible.

What is input and output devices?

INPUT DEVICE:

An input device is a piece of equipment in a computer hardware system that is used to provide data and control signals to an information processing system.

Types of input devices :

There are 2 types of input device are as follows:

- Switches

- Sensors

1. Switches :

Here some example of input devices like switches such as:

- Switches and push buttons

- Limit switches

- Vacuum switches

- Temperature switches

- Level switches

- Pressure switches etc.

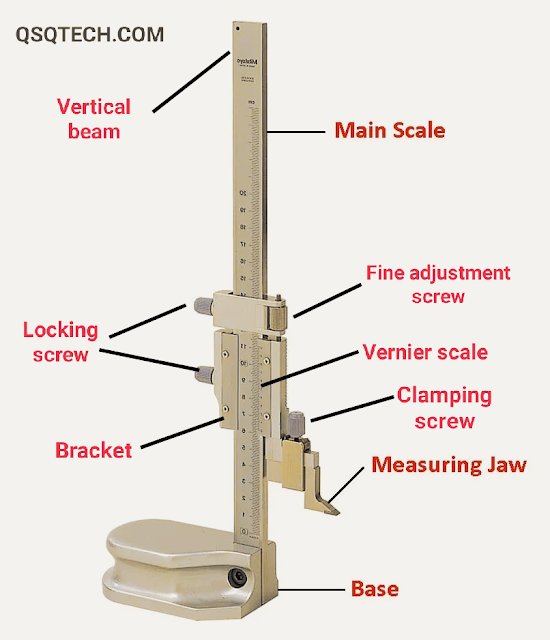

2. Sensors:

Here some example of input devices like sensors such as:

- Sensors and transistors

- Proximity sensor

- Photo electric sensor

- Condition sensor etc.

OUTPUT DEVICE :

An output device is a piece of hardware system used by an IPS to communicate the results of data processing and to translate the information into an understandable form.

Some examples of output devices are like:

- Valves

- Motor starter

- Horns and Alarm

- Control relays

- Stack lights

- Pumps

- Printers

- Fans etc.

SCADA :

The full form of SCADA is Supervisory Control and Data Acquisition. It is a graphic that supervise the overall system and also collect overall data. At assembly production line, with help of all sensors, SCADA system is collect all information that input from sensors and showing images at a screen that missing cases, wrong assembly, BOPs or other child parts assembly not done at correct position. It is a system of software and hardware elements that interfaces with all the PLCs through the network. SCADA system include a human interface, usually in a central location such as a control room, to monitor processes, generate alarms, and allow the operator to intervene or override as needed.

This situation has given rise to large-scale supervisory control and data acquisition (SCADA) systems.

Fundamental basics of a SCADA System:

SCADA (Supervisory Control and Data Acquisition) is allowing industrial organisations to:

- Control the industrial process locally or by remotely.

- Monitor, gather, and process the real time data

- Direct interaction with output devices such as pumps, motors, sensors, valves and more through HMI (Human Machine Interface) software

- All these events or data store in log file.

The basic Architecture of SCADA System:

The basic architecture of SCADA system starts with PLC (Programmable Logic Controller) and RTU (Remote Terminal Unit). PLC and RTU are microcomputers which communicate with the interface of external devices like machinery, sensors, HMI (Human Machine Interface) and then transfer the information from these external devices to SCADA software based computer. The SCADA system collects, processes and distributes all the information, displays data that helps to analyze the data for the operator or other employee so he or she makes the necessary decisions.

We hope you will understand this topic.

Thank you.

Some important question that you should read to improve skill:-